International Online Workshop: Particle Technology and Product Design Education – A Digital Leap Forward (Workshop Review)

On 10-11 May 2021, university lecturers, industry representatives and students gathered online for the workshop “Particle Technology and Product Design Education – A Digital Leap Forward”. The workshop was organized jointly by the Collaborative Research Center 1411 “Design of Particulate Products” of FAU and the International Fine Particle Research Institute (IFPRI) An IFPRI-sponsored workshop in April 2017 at The University of Sheffield, UK reinforced the need for greater cooperation within the particle science and technology community regarding education in the field. In particular, colleagues from industry highlighted the general lack of key competences of new graduates in particle-related topics, while lecturers demanded that relevant aspects of particle technology and product design are integrated to a greater extent in core engineering subjects. Moreover, there is a considerable need for the focus to widen from traditional particle technology unit operations to include product design for multiphase systems for a wide range of application fields.

Four years on from the previous workshop and following a year of emergency online teaching, new approaches to the way engineering competences are delivered to students have been highlighted. At the 2021 workshop, over two afternoons, talks and discussions were devoted to the status of the particle technology and product design curriculum and also highlighted new opportunities for online and blended learning, many being directly catalysed by the COVID-19 pandemic. The workshop, which was free of charge, was targeted towards all those involved in university teaching and continuing education in particle technology and closely related fields as well as to industry representatives and those looking to collect or share experience regarding digital teaching methods in engineering.

Day 1: The Curriculum

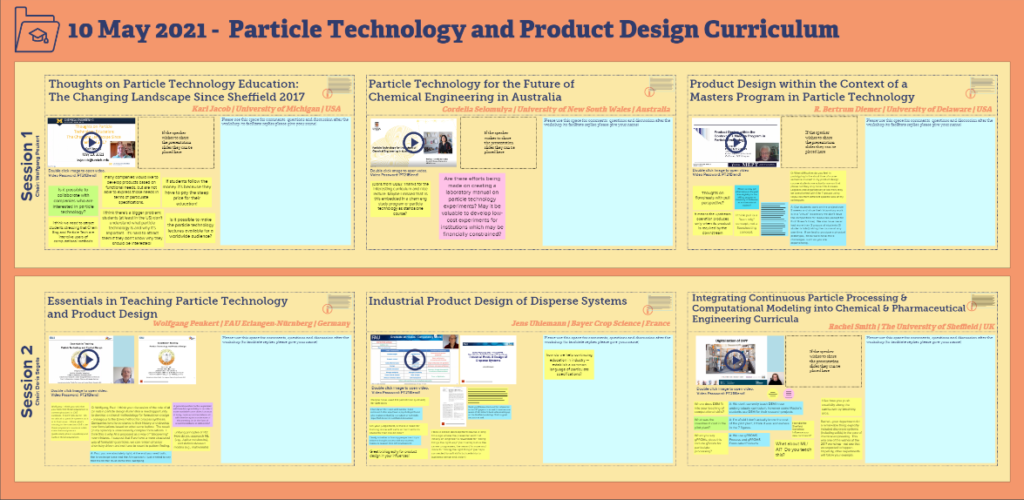

Over 175 registrations from 26 countries were received for the workshop, which was realised using two complementary platforms, zoom and MURAL (see images) for video conferencing and virtual whiteboard-based discussion respectively. The first day opened with short statements from the workshop organizers, Wolfgang Peukert and Robin Klupp Taylor of FAU and Jim Michaels of IFPRI. Although unable to attend live, the FAU Vice President Education Bärbel Kopp warmly welcomed participants to Erlangen virtually via a recorded greeting which also provided some facts about the university and highlighted the long heritage at FAU for innovative teaching.

The main focus of the first day was on the status of the particle technology and product design curriculum. Over six talks, colleagues from universities in the USA, UK, Australia and Germany, and from industry shared their opinion on the situation in their countries and institutions and gave insight to the topics that they teach. Participants got to learn about various global challenges which demand shifts in emphasis in chemical engineering programmes in general and particle technology in particular. These include the ban of plastic waste imports to China and the need, as exposed by the COVID-19 pandemic, not to become too reliant on global supply chains for particle-based commodities such as pharmaceuticals and medical products.

Various approaches to integrating particle technology and product design into degree programmes were demonstrated. For instance, as shown in the talks of Cordelia Selomulya (UNSW Sydney), Rachel Smith (University of Sheffield) and Wolfgang Peukert (FAU), in Australia, UK and Germany, particle technology is often included in the core chemical engineering curriculum either as a course in its own right or integrated into courses on fluid and solid mechanics, process analysis or transport phenomena. Rachel Smith’s talk demonstrated how consideration of graduate destinations enabled a complete overhaul of the chemical engineering curriculum in Sheffield with the result that particle technology could play an even stronger role due to its critical contribution in key fields like food and pharmaceuticals. The situation in the USA, as depicted in talks by Karl Jacob (University of Michigan) and Bert Diemer (University of Delaware) is currently less positive. There, significant student training in particle technology has been rather exclusive to elective classes or Master’s programs. However, due to retirement of key faculty, lack of departmental support and the reduction in chemical engineering student enrolments, the already few opportunities are becoming even fewer. At the same time, the demand from industry for graduates with competencies in particle technology has, if anything, increased. It is therefore critically important that industries coordinate e.g. through IFPRI to apply pressure on chemical engineering departments to avoid creating a large skills deficit. An opportunity for this would be on the topic of product design and the talks by Bert Diemer (University of Delaware) and Jens Uhlemann (Bayer Crop Sciences), demonstrated how key industrial design approaches can be communicated to senior students, through a capstone or elective classes.

Day 2: Blended Learning

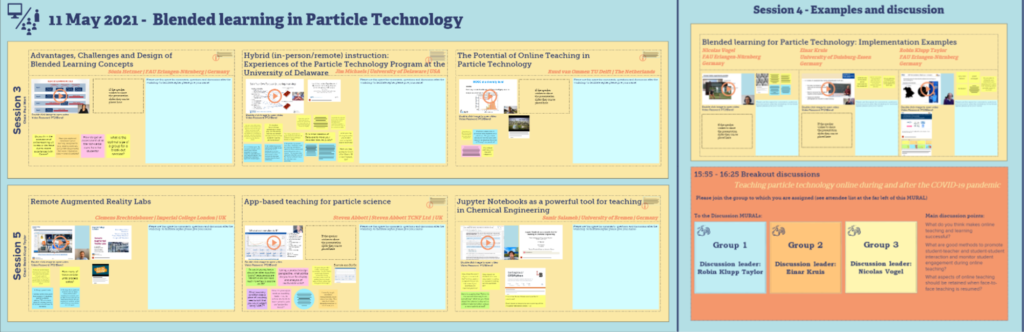

Blended learning aims to combine the advantages of asynchronous learning with the necessary synchronous interactions between students, their peers and their teachers. Although universities have engaged themselves for many years with online and blended learning methods, uptake has varied considerably across the subject spectrum. In the fields of chemical engineering in general and particle science and engineering in particular, blended learning has not been widely implemented. The COVID-19 pandemic has thrust digital-oriented teaching into the spotlight and may provide the catalyst for a sea-change in the approach to higher education in the Engineering sciences. Nevertheless, the wide range of opportunities, challenges and solutions associated with blended learning brings the risk that traditional face-to-face teaching is replaced by a variety of disparate approaches at different institutions or even within them. This could result in a confusing situation, not only for students themselves but also for lecturers and for future employers who wish to identify the most suitably trained candidates. Consequently, networking between university educators in the relevant fields is more critical than ever. After nearly a year of “emergency online teaching”, it is important for our field of particle science and engineering to take stock, highlight best practices, identify shortcomings and chart out a sustainable course for the future. To this end day two of the workshop comprised a combination of presentations covering relevant elements of blended learning for engineering teaching with a breakout discussion where colleagues can share their own (recent) experiences.

The afternoon started with a talk by a specialist on blended learning, Sonía Hetzner from FAU’s Center for Digital Transformation in Education. This introduced participants, from a didactic standpoint, to the various scenarios for blended learning. After this general introduction, the remaining talks of the day were given by engineering lecturers or specialists and these illustrated blended learning approaches or tools to support digital teaching and learning. Jim Michaels (University of Delaware) talked about how a Particle Technology Masters Course was successfully delivered in a hybrid format long before the pandemic. He went on to propose the development (spearheaded by IFPRI) of a virtual textbook based on short instructional videos on various aspects of particle technology. This would be a “living” resource because the choice and order of videos would depend on the overall learning objective of the viewer.

Some universities have embraced the concept of massively online open courses (MOOCs) particularly as a means to offer excellent qualification to remote learners particularly those in developing or emerging economies. Ruud van Ommen of TU Delft gave details of his and colleague’s experience with this approach to teaching (especially through the edX model). He also demonstrated how online teaching and assessment (quizzes with limited number of retakes) can lead to improvement in grades of students of “normal” university courses.

In the middle of the afternoon there was a short session during which three particle technology lecturers from Germany gave examples of how they have embraced blended learning in their teaching. Here, Nicolas Vogel (FAU) spoke about how he developed lecture videos for youTube which combined “old style” teaching with experiments and audience participation. Einar Kruis (University of Duisburg-Essen) showed how an inverted classroom approach based on high quality videos, quizzes and exercises delivered to students via the moodle platform could lead to significant improvement in grades in a course on Nanoparticle Science and Engineering. Taking a similar approach, Robin Klupp Taylor (FAU) gave details of how he taught Particle Technology, in particular making uses of the ILIAS learning management system, H5P interactive videos and MURAL online whiteboard to enable student questions and support live class discussions and activities. Following the examples sessions, workshop participants split into three breakout groups and the speakers of the session led discussion on experiences of blended learning.

The final session of the workshop highlighted how advanced tools and computer platforms can transform the learning opportunities for students. Clemens Brechtelsbauer (Imperial College London) talked about how the chemical engineering practical labs were transformed since 2015 with the commissioning of numerous rigs to lead students through a “discovery-based” learning process. He went to show how, in response to the COVID restrictions, these rigs could be enabled for mixed reality and remote control operation by students. Following this Steven Abbott, an independent consultant dedicated to solving tricky formulations and coatings problems, encouraged participants to bring clarity to their teaching and research through “appification” i.e. the visualization of multiparametric phenomena. To provide motivation he highlighted a number of particle-related examples from his highly acclaimed website and YouTube channel. Another approach to help students get to grips with complex concepts was provided in the the final talk by Samir Salameh (University of Bremen). This introduced participants to JuPyter Notebooks, an online interactive programming environment which can be used to support students’ transition from basic knowledge towards understanding and application. Through the example of a notebook concerning distillation of liquids according to Raoult’s law Samir showed how students are led through a seamless page of text, videos and executable code. This clever way of consolidating both chemical engineering and programming competences brought the workshop to its conclusion.

Programme, Speakers and Abstracts

All talks were recorded. For access to the videos please contact the workshop organizer.

| 14:30 |

|

|||

| 14:45 |

The International Fine Particle Research Institute held a particle technology education workshop in Sheffield, UK in April 2017, which examined many different aspects of the challenges for all of us in this area (Powder Tech, (2020), 360, 144.). Even though it is just four short years after that workshop, our world has changed significantly and this is especially true in the education space. However, many of the outcomes of the meeting remain very valid: the need to educate undergraduates in the field; the continuing battle to get support for solids processing technology both for the undergraduate curriculum and PhD research; the desire by industry to have well-trained engineers at all degree levels. With the onset of the Covid-19 virus in early 2020, we’ve had to embrace both the delivery of education remotely and doing industrial particle technology development virtually with minimal experiments. We will examine the effectiveness of virtual delivery of particle technology engineering education across all levels (UG, grad, and post-grad) and where significant challenges still remain. In addition, I will highlight the importance of teaching each other so that we may teach our students better. Lastly, I will offer some thoughts on the path forward for education in OUR field.

Karl Jacob is a retired Fellow in Engineering Sciences at The Dow Chemical Company. He is the founder of the Solids Processing Lab at Dow. Presently, he teaches solids processing and assists with process design at the University of Michigan. He is an AIChE Fellow and a graduate of Case Western Reserve University. For nearly the last four decades, he has worked on a vast array of particle technology problems, with particular expertise in silo/hopper design, powder mechanics, pneumatic conveying, particle engineering. |

|||

| 15:15 |

The talk will provide an overview of how particle technology education is being delivered in Australia with an example of the program offered at the School of Chemical Engineering at UNSW Sydney. The School offers coursework degrees in Chemical Engineering, Chemical Product Engineering, and Food Science at undergraduate level, and Master of Engineering Science specialising in chemical and food process engineering at postgraduate level. The fundamental properties and processes of particulate materials, and modelling approaches are offered as part of the core subjects at 2nd and 3rd year levels. The more advanced applications of particle technology are embedded in several discipline electives at both undergraduate and postgraduate levels, including in complex fluids microstructure, nanotechnology, food / pharmaceutical processing, and heterogenous catalysis. The talk will cover the potential direction for particle technology education for future engineers in the Australian context.

Prof. Cordelia Selomulya joined UNSW Sydney in December 2019 as a Professor in the School of Chemical Engineering and as a Research & Commercialisation Director of the Future Food Systems CRC. She is leading a research group with an internationally recognised reputation in drying technology research, particularly for functional particle assembly via microfluidic spray drying. She was the recipient of IChemE Global Awards in Food and Drink category (2018) for the best project, process or product that demonstrates innovation to optimise manufacturing operations and contribute to the manufacturing of safe, sustainable food or drink, BHERT (Business & Higher Education Round Table) Award (2018) for outstanding collaboration in R&D for the Food and Dairy industries, and Fonterra Award (2017) for outstanding contribution in the industrial application of a novel technology in the field of bioprocessing. She was recently elected as a Fellow of the Australian Academy of Technology and Engineering (2020). At UNSW, she is continuing her work to develop new functional dairy ingredients via spray drying, in collaboration with Penn State and Soochow Universities, supported by the Australian Research Council (ARC) Discovery program. She is collaborating with Jacobs Douwe Egberts to improve spray-dried powder properties for beverage applications, EcoMag Ltd for spray drying of magnesium powders for nutraceutical applications, and Sanitarium Health Food Company to optimise their plant-based products. |

|||

| 15:45 |

This talk describes the Master of Engineering in Particle Technology program offered at the University of Delaware from 2014-2020 and its capstone element, a course titled Particle-Based Product Engineering. The full program consisted of six core courses, four of which focused on fundamentals while two focused on applications. The fundamentals courses built a foundation of understanding in particle properties and characterization, particle formation and transformation kinetics, mathematical modeling of particle systems and particle transport in powders and slurries. The two applications courses utilized this foundation to focus on:

|

|||

| 16:15 | Break (15 Minutes) | |||

| 16:30 |

Product design is the formation, formulation, handling, manufacturing, and characterization of complex multiphase products with specific properties. The applications define the required product properties, which cover both classical fields of process technology in the chemical industry as well as new emerging fields of electronics, energy and environmental technologies, life sciences, materials science and engineering, nanotechnology, and photonic technologies. In view of the broad relevance of particle science and technology, the challenge is how to prepare students to tackle the grand challenges in particle science and technology in academia and industry.

|

|||

| 17:00 |

This contribution aims to provide a personal industrial perspective on higher education in product design and particle technology that builds on the 2017 Sheffield workshop and on own extensive experience in the industry sectors flavors and fragrances, material science, pharmaceutics, and pesticides. The personal perspective is based on 10 years of teaching a master’s class class in the field and on more than 25 years of industrial experience.

After studies of chemical engineering at the Technical University Clausthal / Germany, at the Ecole Nationale Supérieure de Génie Chimique de Toulouse / France and at the University of California at Berkeley / USA, Dr. Jens Uhlemann worked with Bayer (from 1993 to 1997 and since 2008) and with Symrise (from 1997 to 2008), a global leader in the Flavor & Fragrance industries in various R&D and product supply roles. He has been active in the particle technology / product design and innovation management field since 1997. Since 2020, he is responsible for global regulatory affairs of the Bayer business unit Environmental Science. In the same year, he was appointed as Honorary Professor at the Institute of Particle Technology of the Friedrich-Alexander-University Erlangen-Nuremberg / Germany. His current focus is on developing new and innovative options. |

|||

| 17:30 |

Since 2017, the Department of Chemical and Biological Engineering at the University of Sheffield has been implementing a new undergraduate curriculum. Additionally, a new MSc course in Pharmaceutical Engineering has commenced. In both curricula there is significant emphasis on particle technology, acknowledging the importance of particulate products to manufacturing industries worldwide. In this presentation, relevant changes and new inclusion to the curricula are highlighted. Of particular note is the integration of a continuous pharmaceutical processing facility (the GEA Consima 25), consisting of a twin screw granulator, fluid bed dryer, milling and tableting steps. Additionally, the use of computational population balance modelling for particulate processes has been introduced to both the undergraduate and the postgraduate taught curricula, and the opportunities and challenges this presents will be discussed.

Dr Rachel Smith is a Senior Lecturer in the Department of Chemical and Biological Engineering at the University of Sheffield, with expertise in industrial particulate manufacturing across pharmaceutical, agri-chemical, consumer and battery manufacturing industries. Her research focuses on the development of micro-scale knowledge of particle-particle and particle-fluid interactions, and using this to advance mechanistic understanding of particulate manufacturing processes and product performance. Processes of interest include granulation, particle coating, spherical agglomeration, and fluidized bed processes. Her work uses both experimental and computational methods to address industrial particle processing opportunities and challenges. Rachel holds a BEng (Hons) and PhD from the University of Queensland, Australia, and joined the University of Sheffield in 2012.

|

|||

All talks were recorded. For access to the videos please contact the workshop organizer.

| 13:45 |

The term blended learning stands traditionally for the blend of offline and online teaching. With the pandemic and the lockdown of university campuses the term has evolved to a combination of synchronous and asynchronous teaching opening for new opportunities in teaching but also demanding new skills and competences for university lectures. In the scope of the presentation the advantages, the challenges and the design principles for facilitating blended learning in higher education teaching are explained and discussed.

|

|||

| 14:15 |

The Master of Engineering in Particle Technology program at the University of Delaware was originally conceived as a conventional residential instructional program. Early in our first year (2014), we received a request from a working engineer in Vermont,400 miles distant, to complete the program remotely. Realizing that employed engineers represented a significant market for the program, we implemented changes in how we delivered our courses to allow simultaneous attendance by residential and remote students. In this talk, I will discuss those changes and the tools (hardware and software) we used to facilitate hybrid instruction. Overall, we found the conversion to be flexible to teaching style, inexpensive, and simple to implement. Perhaps the most significant lesson we learned was that providing education in particle technology to working engineers is an important and largely unmet need. Most working engineers are unable to take full courses on an academic schedule, therefore other channels for delivering content need to be developed. I will describe a “straw man” for one approach that is being prototyped by the International Fine Particle Research Institute (IFPRI).

|

|||

| 14:45 |

TU Delft offers various MOOCs (Massive Open Online Courses) on the edX-platform. A MOOC is an online course aiming at large-scale interactive participation and open access via the web. There is not yet such a MOOC on Particle Technology available in Delft, and – as far as I am aware – there is also little openly available online material in this field at other universities. In this presentation, I will briefly show how a MOOC can work, and discuss its pros and cons. I will also present some other ways on (partial) online teaching. Subsequently, I will discuss how these approaches could be applied to the field of Particle Technology.

|

|||

| 15:15 | Break (10 Minutes) | |||

| 15:25 |

In three short talks, different examples will be given regarding how particle technology and related subjects have been taught using hybrid and digital methods.

|

|||

| 15:55 | Breakout Session: Teaching particle technology online during and after the COVID-19 pandemic | |||

| 16:25 | Break (5 Minutes) | |||

| 16:30 |

|

|||

| 17:00 |

Modern internet infrastructure makes it easy to bring equations to life on a phone, tablet or laptop, allowing us to explore what a theory means by changing input values and instantly seeing the numerical and graphical results. My own site with 350+ apps gets 250,000 visitors a year keen to explore science “live”. The hard part of writing an app is the interface – but that’s readily solved via a good, standard, infrastructure. Writing the code to do the calculations is generally trivial – modern JavaScript is so powerful, with many powerful libraries. In this talk you will be shown the tools that could get you appifying your own science in a couple of afternoons. There’s one more thing: ‘If it’s not on YouTube then it doesn’t exist’, so putting your app onto YouTube greatly expands its reach.

Prof. Steven Abbott is well-known for his Practical Science website and YouTube channel where he tries to make powerful science usable to the wider community. He is a chemist with a PhD from Oxford/Harvard and after 30 years in industry (plus becoming a Visiting Professor at U Leeds) set up as a consultant to help troubleshoot problems around the world while attempting to give away his knowledge with free eBooks and apps. |

|||

| 17:30 |

By combining the two worlds of written documents and coding environments, Jupyter Notebook offers a hugh variety for explaining and training concepts of chemical engineering to students. In this way Jupyter Notebook can be used to explain theoretical and practical knowledge in a very apparent and comprehensible way, creates an environment for students to train these concepts in their own speed of learning, or give them full exercises to challenge their knowledge. By designing their own Notebooks students can independently work on topics of interest within the lecture. Therefore, we want to share our experiences in this talk of using Jupyter Notebook as an excellent tool for (online) teaching in chemical engineering classes during the last year.

|

|||

| 18:00 | End of Workshop | |||

Jointly organized by: |

Contact |

|

Prof. R. Bertrum Diemer has over 40 years of experience at Dupont Company where he developed and improved products and processes via applied expertise in reaction engineering, thermochemistry, and population balance modeling. During that time he never lost sight of the importance of first class chemical engineering education and was Adjunct Professor at the

Prof. R. Bertrum Diemer has over 40 years of experience at Dupont Company where he developed and improved products and processes via applied expertise in reaction engineering, thermochemistry, and population balance modeling. During that time he never lost sight of the importance of first class chemical engineering education and was Adjunct Professor at the  The attributes required in a graduate engineer are defined from that perspective, to support the establishment of a suitable syllabus. Three additions to the 2017 Sheffield concepts are proposed: (i) case study-based approaches for holistic understanding, (ii) extension of single-phase particle to multiphase disperse systems and (iii) a focus on digitalization. The graduate engineer will thus be enabled to personally grow according to personal strengths and aspirations, to compete successfully in the dynamic labor market and to thrive in an industry that is driven by an extensive change agenda related to the keywords of innovation, sustainability and digitalization.

The attributes required in a graduate engineer are defined from that perspective, to support the establishment of a suitable syllabus. Three additions to the 2017 Sheffield concepts are proposed: (i) case study-based approaches for holistic understanding, (ii) extension of single-phase particle to multiphase disperse systems and (iii) a focus on digitalization. The graduate engineer will thus be enabled to personally grow according to personal strengths and aspirations, to compete successfully in the dynamic labor market and to thrive in an industry that is driven by an extensive change agenda related to the keywords of innovation, sustainability and digitalization.

Sónia Hetzner holds a diploma in Sociology, Geography, Politics and Biology from the FAU Erlangen-Nürnberg. She has been a senior researcher at the

Sónia Hetzner holds a diploma in Sociology, Geography, Politics and Biology from the FAU Erlangen-Nürnberg. She has been a senior researcher at the  Prof. Ruud van Ommen has been a member of the Department of Chemical Engineering at TU Delft since 2001 and has been Antoni van Leeuwenhoek Professor there since 2016. He is active in the fields of particle technology and chemical reaction engineering, with particular focus on the scalable production of advanced, nanostructured materials. In 2011, he started an ambitious programme (funded by an ERC Starting Grant) to investigate the interplay between agglomeration and coating of nanoparticles in the gas phase. This fundamental work has been leading to multiple practical applications in health and energy applications, funded by several research grants and by industry. It has also led to a spin-out a company (Delft IMP).

Prof. Ruud van Ommen has been a member of the Department of Chemical Engineering at TU Delft since 2001 and has been Antoni van Leeuwenhoek Professor there since 2016. He is active in the fields of particle technology and chemical reaction engineering, with particular focus on the scalable production of advanced, nanostructured materials. In 2011, he started an ambitious programme (funded by an ERC Starting Grant) to investigate the interplay between agglomeration and coating of nanoparticles in the gas phase. This fundamental work has been leading to multiple practical applications in health and energy applications, funded by several research grants and by industry. It has also led to a spin-out a company (Delft IMP).

Dr. Clemens Brechtelsbauer is Director of Chemical Engineering Education and Teaching Fellow at Imperial College London. Following his diploma and doctorate at the FAU Erlangen-Nürnberg he spent 13 years in industry, in process engineering and process engineering management, at GlaxoSmithKlein. As a Teaching Fellow, his research at Imperial College concerns experiential learning, particularly participatory design: This takes techniques proven to be successful in modern project management and applies them to an educational setting. One key feature is involving students as major stakeholders in designing their own learning.

Dr. Clemens Brechtelsbauer is Director of Chemical Engineering Education and Teaching Fellow at Imperial College London. Following his diploma and doctorate at the FAU Erlangen-Nürnberg he spent 13 years in industry, in process engineering and process engineering management, at GlaxoSmithKlein. As a Teaching Fellow, his research at Imperial College concerns experiential learning, particularly participatory design: This takes techniques proven to be successful in modern project management and applies them to an educational setting. One key feature is involving students as major stakeholders in designing their own learning.

Dr. Samir Salameh worked as a Project Leader in R&D for Saint Gobain Sekurit in terms of tempered glass and functional coatings. He studied Industrial Engineering and Management at the University of Bremen, where he focused on particle technology for a PhD in the group of Prof. Lutz Mädler. His major research topic are physical forces on the nanoscale which he continued as a Post-Doc in the group of Ruud van Ommen at the TU Delft. During this time he got a scholarship to visit various research group around the globe and gave seminars. He frequently attends in science communication events such as Science Slams, or the

Dr. Samir Salameh worked as a Project Leader in R&D for Saint Gobain Sekurit in terms of tempered glass and functional coatings. He studied Industrial Engineering and Management at the University of Bremen, where he focused on particle technology for a PhD in the group of Prof. Lutz Mädler. His major research topic are physical forces on the nanoscale which he continued as a Post-Doc in the group of Ruud van Ommen at the TU Delft. During this time he got a scholarship to visit various research group around the globe and gave seminars. He frequently attends in science communication events such as Science Slams, or the