CRC 1411 researchers advancing field of plasmonics with innovative continuous flow synthesis

A team of scientists at CRC 1411, led by Prof. Dr. Robin Klupp Taylor, has made a significant step forward in the realm of plasmon resonant nanoparticles. These could find applications in diverse fields, such as medical diagnostics, drug delivery, biosensors, photocatalysis and pigments. Their paper, ‘Gram-Scale Continuous Flow Synthesis of Silver-on-Silica Patchy Nanoparticles with Widely Tunable Resonances for Plasmonics Applications‘, recently published in the journal ACS Applied Nano Materials, presents a novel and efficient synthesis process for creating noble metal nanostructures with high application potential.

The “problem” with plasmonic nanoparticles

In general, “plasmonics” explores how the interaction between light and metals can be adjusted through structuring materials on the nanometer scale. Specifically, gold and silver nanoparticles display unique and captivating colors which result from free-electron resonances that can be tailored for various applications. Scientists have known for a long time that these colors can be tuned by adjusting the shape of the nanoparticles. But there’s a catch, as Prof. Klupp Taylor explains: “Tunability, scalability and reproducibility have been major challenges in the plasmonic nanoparticles field. Many researchers have demonstrated exquisite control over nanoparticle shapes and colors but could not reproduce these on the large scale necessary for applications. Others have focussed on scalability, but can only produce one type of nanoparticle, with limited color tunability. Our research addresses these issues by combining a unique material system with the use of gold nanocrystal seeds and continuous flow synthesis.”

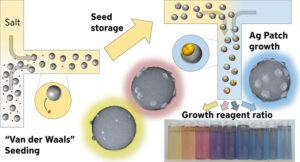

This breakthrough research uses tiny gold nanocrystals – similar to those found in lateral flow COVID-19 tests – to determine where curved silver patches grow on glass nanospheres. It is the silver that gives the particles their unique color. The inclusion of the gold seeds, which the researchers could affix to the glass much like a gecko sticks to the ceiling, allows a high degree of control and predictability in the production process.

A paradigm shift in complex nanoparticle synthesis

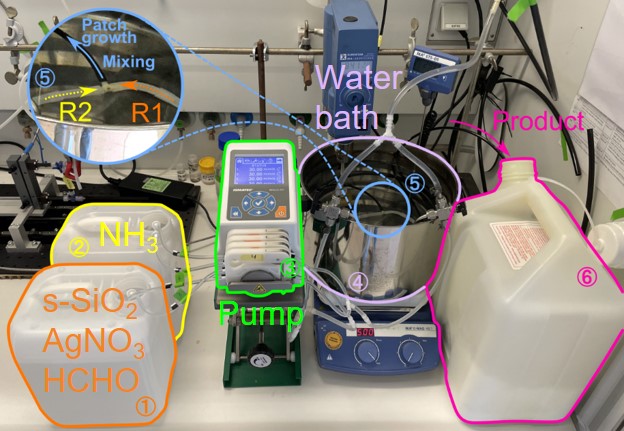

However, the innovation did not stop there. Using continuous flow synthesis, instead of traditional “cooking pot” methods, the team has overcome the limitations posed by mixing for large batch volumes. This results in more control and the potential to produce larger quantities of these nanoparticles. First author Andreas Völkl, a doctoral researcher from the Nanostructured Particle Research Group, who set up the process to produce the nanoparticles, discussed the significant benefits continuous flow brings to nanoparticle synthesis: “Gone are the days of laboriously cleaning out beakers and test tubes, only to potentially run into issues with contamination messing up the consistency of our batches. Now we’re working with tubing that’s not only easier to keep clean, but also ensures much higher reproducibility. And honestly, it’s pretty neat to have a tap in the lab where you open it and out flows a rainbow of nanoparticles. It’s high-tech, it’s cleaner, and it’s making our work easier and more reliable.”

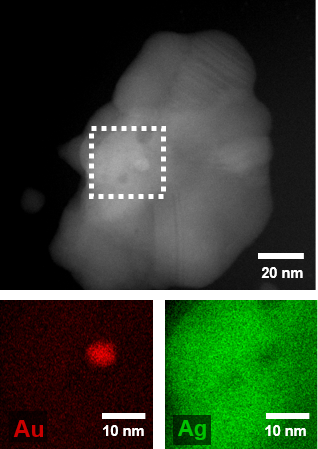

Insights from advanced electron microscopy

The research was part of the DFG-funded Collaborative Research Center 1411 “Design of Particulate Products” and called on project partners from the Institute of Micro- and Nanostructure Research to apply some of the most advanced electron microscopy techniques to provide insight into the nanostructure shape and composition. Dr. Benjamin Apeleo Zubiri, who supervised these characterisation studies, explained how one of the biggest challenges was trying to find the tiny gold seed nanoparticles in the centre of the silver patches: “It sounds a bit like finding a needle in a haystack. However, thanks to the microscope’s X-ray spectrometer, we can get silver and gold to show up differently. Then it is just a question of keeping a good lookout!”

Looking to the Future: Applications in Pigment Technology?

The team’s focus now shifts towards exploring the applications of their groundbreaking research, particularly in pigment technology.

“We’re very excited about the future of this research,” Prof. Klupp Taylor adds. “Beyond advancing our understanding of the patch growth mechanism and transferring it to non-noble metals, there is a vast potential for these particles in energy and pigment technology and other areas where such materials have not yet been extensively investigated.”

Images reproduced with permission from https://pubs.acs.org/doi/10.1021/acsanm.3c00869. Copyright 2023 American Chemical Society.

, , , , ,

Gram-Scale Continuous Flow Synthesis of Silver-on-Silica Patchy Nanoparticles with Widely Tunable Resonances for Plasmonics Applications

ACS Applied Nano Materials (2023)

DOI: 10.1021/acsanm.3c00869

Watch a short video introducing plasmonics

Discover the secrets of the Lycurgus cup and why the Romans (sort of) invented nanotechnology

Watch the outreach video “Why silver is not silver and gold is not golden” which was produced by a team of three CRC 1411 doctoral researchers including article first author Andreas Völkl.

Explore the link between metal nanoparticle shape and color in this interactive tool provided by CRC 1411 Mercator Fellow, Prof. Sara Skrabalak (Indiana University)

Learn to use a transmission electron microscope with this fantastic interactive tool provided by microscopy Australia

Prof. Robin Klupp Taylor, MEng, DPhil (Oxon)

Interdisciplinary Center for Functional Particle Systems (FPS)

Friedrich-Alexander-Universität Erlangen-Nürnberg

- Phone number: +49 9131 85-20369

- Email: robin.klupp.taylor@fau.de